Plant Price Liquid Laundry Soap Making SUS Homogenizer Chemical Mixing Machine Detergent Making Mixer Blending Tank Equipment High Speed Dispersion

Plant Price Liquid Laundry Soap Making SUS Homogenizer Chemical Mixing Machine Detergent Making Mixer Blending Tank Equi;

Basic Info

| Model NO. | ZT-300L |

| Certification | CE, ISO |

| Application Area | Daily Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Disc |

| Additional Capabilities | Milling |

| Operating type | Continuous Operating |

| Condition | New |

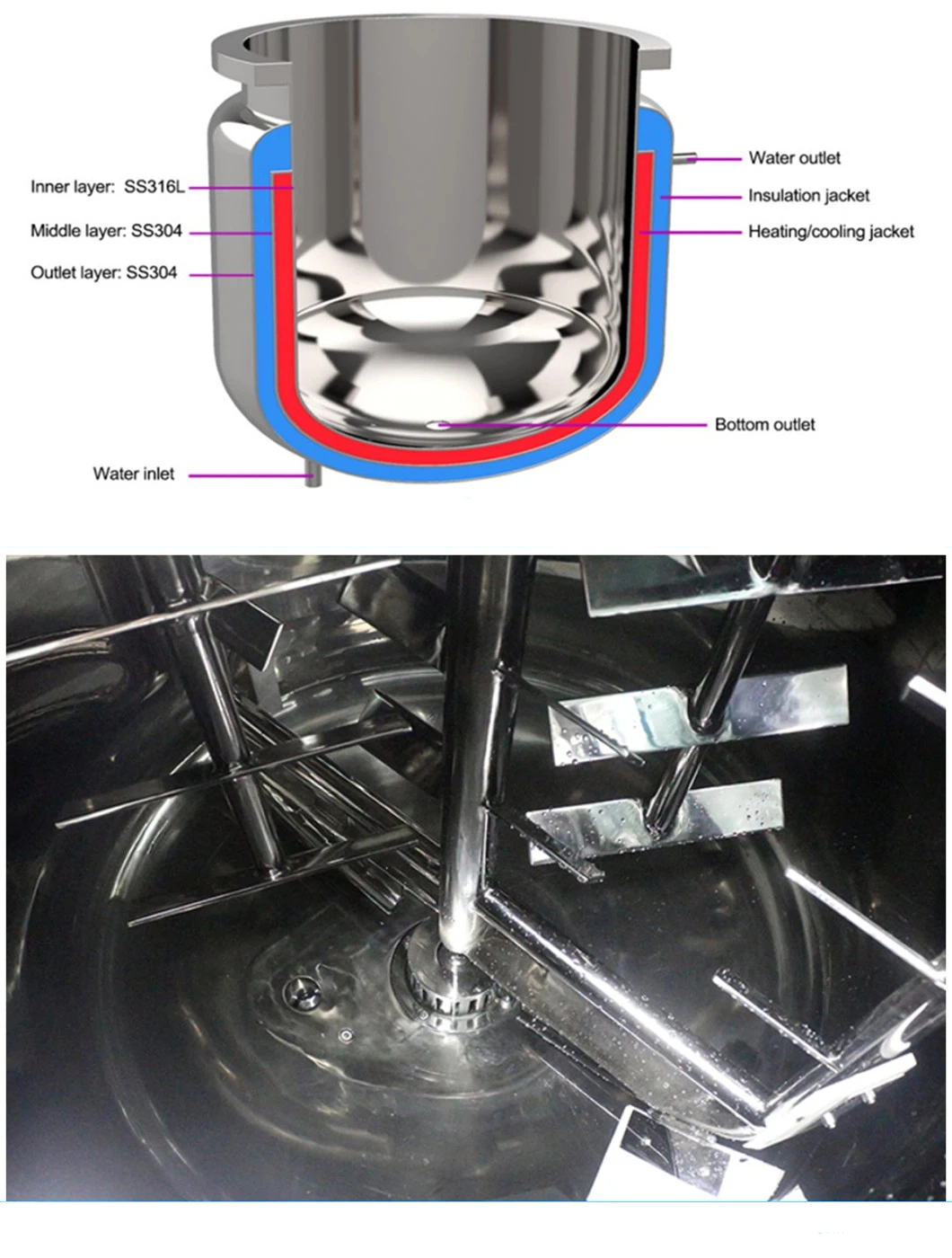

| Advantage | Agitator |

| Capacity | 300L |

| Usage | Daily Chemical |

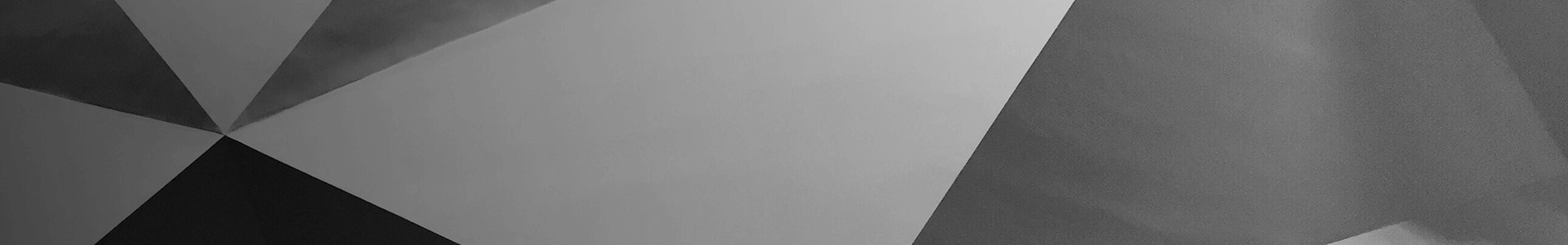

| Material | Stainless Steel 304 / SUS316L |

| Heating | Electric |

| Stirring Speed | 0-63r/Min |

| Function | Homogenizing/Mixing |

| Homogenizer | Upper Homogenizer |

| Voltage | 3 Phases |

| Pot Layer | Single or 3 Layers |

| Transport Package | Wooden Case |

| Specification | 2500*2100*1800 |

| Trademark | self-made |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 3000PCS/Month |

Product Description

Plant Price Liquid Laundry Soap Making SUS Homogenizer Chemical Mixing Machine Detergent Making Mixer Blending Tank Equipment High Speed Dispersion

Capability & Charteristic:

- High speed disperser can powerfully mix and disperse viscous solid and liquid materials, and rapidly dissolve many indissoluble materials such as AES, AESA and LSA during the production of liquid washing products, and thus, saving energy consuption and shortening production period;

- The main blending adopts stepless speed variation device, which can reduce the formation of bubbles when the temperature is low and the viscosity is high;

- The gear pump circulation discharging device can accelerate the forming of products and realize rapid discharging.

Usage:

- Blending reacting boiler is mainly suitable for preparation of liquild detergents (such as cleaner essence, shampoo and shower cream etc). Integrating blending, dispersing, heating and cooling etc. functions, the reacting machine is an ideal device for liquid preparation in various factories.

Latest Research And Development:

- During the production of liquid washing products, the self-suction type AES dissolver can alleviate worker's labor intensity of feeding and shorten dissolving time.

Technical parameter:

| Serial No. | Specification | Volume | Blending power | Blending rotation power | Homogenizing power | Homogenizing rotation speed | Height | Heating method |

| L | KW | r/min | KW | r/min | ||||

1 | E-200 | 200 | 1.5 | 0~65 | 3-4 | 3000 | 2600 | Steam heating or electric heating |

| 2 | E-500 | 500 | 2.2 | 0~65 | 4-7.5 | 3000 | 2700 | |

| 3 | E-1000 | 1000 | 2.2-4 | 0~65 | 5.5-7.5 | 3000 | 2900 | |

| 4 | E-1500 | 1500 | 4-5.5 | 0~65 | 7.5-11 | 3000 | 3050 | |

| 5 | E-2000 | 2000 | 5.5 | 0~65 | 11-18.5 | 3000 | 3150 | |

| 6 | E-3000 | 3000 | 7.5 | 0~65 | 15-18.5 | 1500 | 3400 | |

| 7 | E-5000 | 5000 | 11 | 0~65 | 18.5-22 | 1500 | 3600 |

Note: In case of inconformity of the data in the form due to technical improvement or customization, the real object shall prevail.

Warm welcome to contact us and best service for you.

FAQ:

1

Q:Are you a factory or trading company?

A: We are a factory.

2

Q:How long is the warranty period?

A:All of our products have one year warranty.

3

Q:What's the main market of your company?

A:We have customers all over the world.

4

Q:What's your delivery time and payment terms?

A:Normally,it need about 10-30 days.The exact time depends on your company quality.The payment terms always 70% deposits,30% to be paid before shipment.

5

Q:Can we visit your machine operation in your company?

A:Welcome to our factory to see the machine operation.

6

Q:Where's your factory located?How can we visit there?

A:We are in Yangzhou Industry Zone.Jiangsu province,China.You can take the plane to Zhenjiang airport and we will pick you up there.

Notes:

☆ We'll always be here.Hope to hear a good news from you soon.

☆ If you want to know more details information,such as detail picture,videos and related certification,Pls contact with us.

☆ Should you have any question,please feel free contact us.

☆ Welcome to our company and factory.

If you have any question, please feel free to contact us.

You may also like

Send inquiry

Send now