Spray Type Pre-Treatment Equipment for Spraying and Painting

1.Coating production line The so-called coating refers to covering the metal and non-metal surfaces with a protective la;

Basic Info

| Model NO. | ZM-PLQCL |

| After-sales Service | Overseas Maintenance, Free Spare Parts, Video Tech |

| Warranty | One Year Warranty |

| Type | Electrostatic Spraying Equipment |

| Application | Hardware Spraying Equipment |

| Coating | Powder |

| Certification | CE |

| Method Type | Automatic |

| Condition | New |

| Color | Custom Made |

| Control System | Custom Made |

| Transport Package | Sea, Land |

| Specification | Specification customization |

| Trademark | ZM |

| Origin | Zhejiang, China |

| HS Code | 8424899990 |

| Production Capacity | 1000 Sets/Month |

Product Description

1.Coating production lineThe so-called coating refers to covering the metal and non-metal surfaces with a protective layer or a decorative layer. With the development of industrial technology, painting has developed from manual to industrial automation, and the degree of automation is getting higher and higher, so the application of painting production line is also more and more extensive, and it has penetrated into many fields of the national economy.

According to the characteristics of the workpiece and the technological requirements of the coating, the coating production line includes powder spraying production line, painting production line, electrophoresis production line, etc.

The application range of the coating production line is quite wide.

The powder spraying production line is widely used in most steel sheet industries such as home appliances, transportation, logistics, bicycle frames, elevators, etc.

The spray paint production line is widely used in industries such as wood industry, plastic products, shock absorbers, etc. where the baking temperature is not easy to be too high or non-metallic products.

Electrophoresis production lines are widely used in industries with high surface treatment requirements such as auto parts.

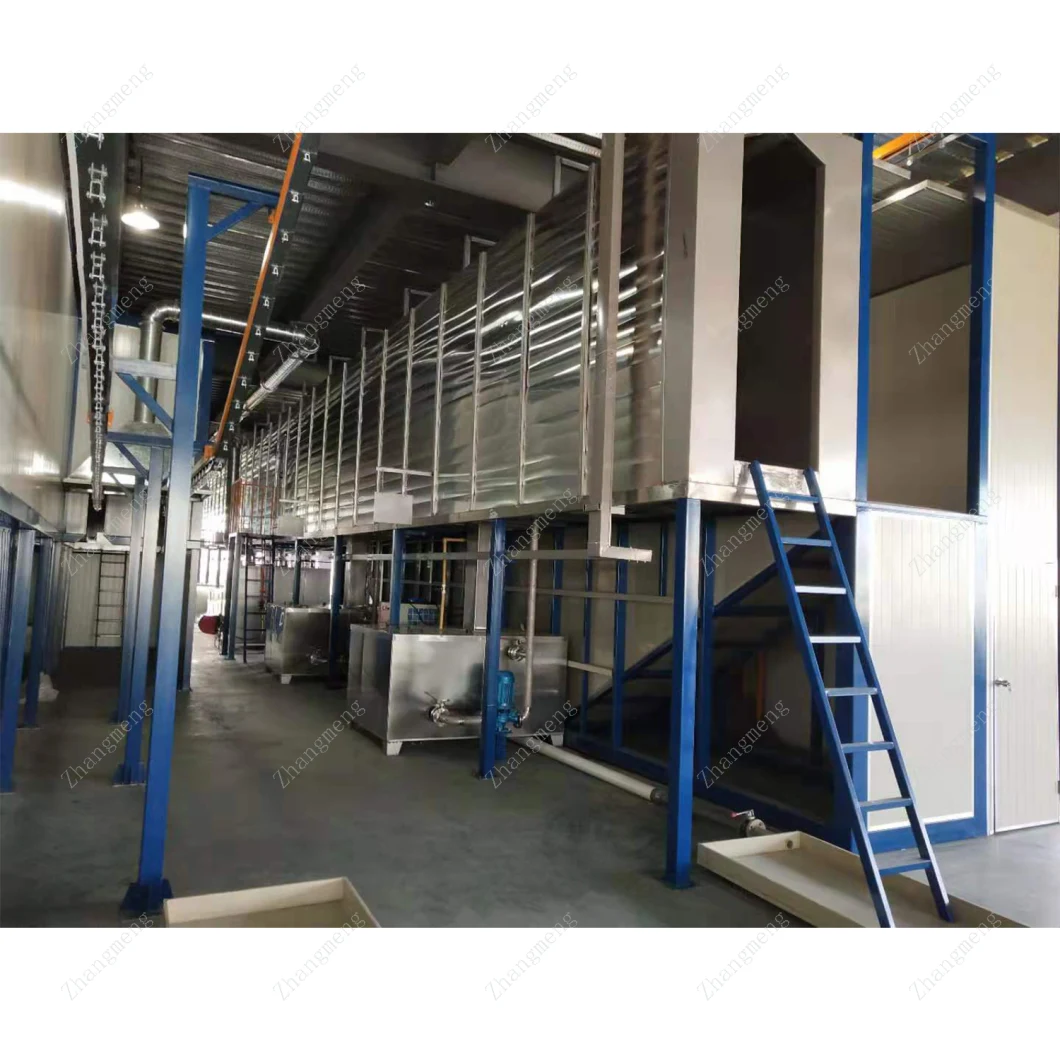

The coating production line is generally composed of seven parts: pretreatment equipment, moisture drying equipment, coating spraying equipment, coating baking equipment, heat source system, product conveying equipment, and electrical control system.

1. Spray-type pre-treatment equipment is a commonly used equipment for surface treatment of metal workpieces. Centrifugal water pumps are used to form high-pressure atomization effects from nozzles through pipes to achieve the purpose of cleaning. liquid, so as to achieve the purpose of environmental protection.

2. The typical process of spray pretreatment is: hot water washing, pre-degreasing, degreasing, pickling, surface conditioning, phosphating, water washing, passivation, and pure water washing.

3. Spray-type pre-treatment equipment consists of: generally shed, tank, exhaust system, pump and spray system, air supply system, catenary protection device, oil-water separation device, heat exchange system, slag removal system, acid Washing system, pure water generation system, temperature control system, electronic control system, etc.

4. The pre-treatment shed body adopts an all-stainless steel cold riveting structure to avoid welding deformation and leakage. The overall equipment is beautiful, practical, durable and easy to maintain.

5. The water supply of the spray pipeline adopts the upward and downward feeding method, which can offset the loss of liquid along the way, keep the spray pressure consistent up and down, and prevent the nozzle from being blocked.

6. The new type can be quickly folded, the direction can be adjusted PP nozzle, the spray system treatment effect.

7. Reasonable length of filter section, no liquid string phenomenon. Degreasing, rust removal, phosphating and cleaning are completed at one time.

8. The water supply of adjacent cleaning tanks in the same process adopts the water flow reverse compensation method, which can improve the utilization rate of water, save chemicals and energy, and reduce the treatment volume of three wastes.

9. The equipment is simple, the floor area is small, and the energy consumption is low, which is suitable for the working state of the tight workshop area. , suitable for small and medium-sized workpieces, and the production volume is large, assembly line production.

10. Each chamber can be independent or combined, and the process is flexible, depending on the specific requirements of the process. , The cleaning operation is simple and can be controlled manually or automatically.

3.Customer case

Our company has a huge annual output and provides services to customers all over the world. It has formed an assembly line operation mode. There is a complete set of processes in the pre-sale, in-sale and after-sale processes. Customers buy, this is the praise and feedback from customers.

4. After-sales guarantee

(1) In the 16 years since its establishment, it has delivered tens of thousands of sets of equipment to all parts of the world. How to ensure after-sales service? First of all, our company's products all adopt the method of modular components, each unit is an independent individual, which can be replaced by quick disassembly and assembly.

(2) We have a professional team, all-weather guarantee one-to-one quick connection, feedback.

As long as it is exported, we use fumigated wood packaging for small pieces, and container-style packaging for large pieces to avoid damage.

(1) Industry gathering

(3) company team

You may also like

Send inquiry

Send now